PROCESS

DLC taC is an acronym for diamond-like carbon. DLC taC has some of the valuable properties of diamond, including: high hardness, low friction, resistance to wear, chemical inertness, biological compatability, electrical insulation, optical transparency, and smoothness.

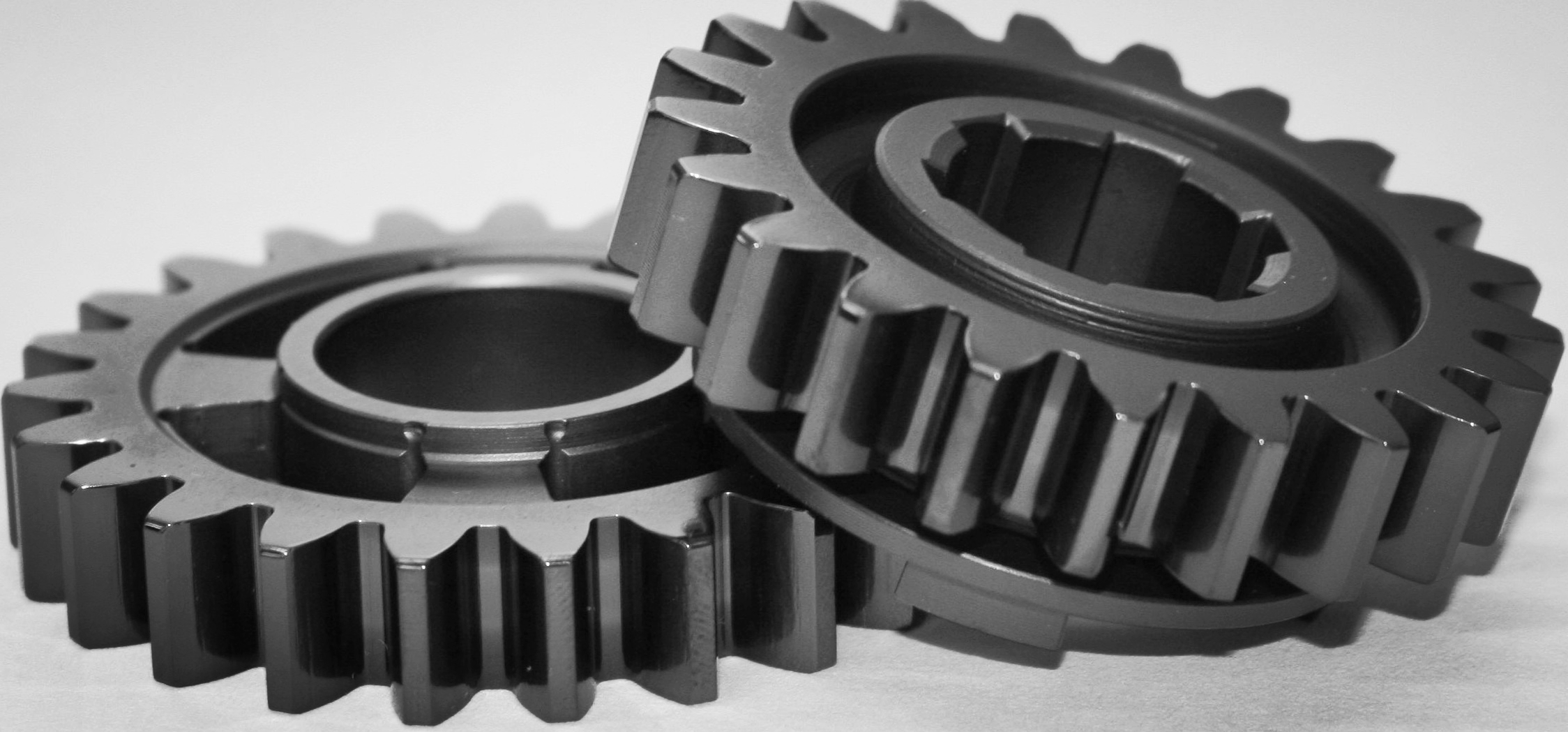

In common terms, DLC TaC is harder than natural diamond and slicker than "Teflon." DLC coatings are used to impart some of the useful characteristics of diamonds onto other materials. DLC coatings can be deposited on nearly all metals, metal alloys, and also on nonmetals such as silicon, glass, ceramics, plastics, etc. DLC TaC can be deposited at low (<100C) substrate temperature. DLC TaC coating has many commercial applications, including machine tools, aerospace parts, automotive engine parts, medical implants, and high-end watches. Depending on the application, different formulations of DLC coatings are used.

Characteristics

- High hardness

- Low coefficient of friction (0.02 - 0.15)

- High corrosion resistance

- Great adhesion to substrate material

- Fretting resistance

- Adhesive wear resistance

- Self lubrication in dry wear conditions

- Excellent release properties

- Electrical insulation

Applications

- Cutting tools for aluminum, aluminum-silicon alloys, powder metallurgy alloys

- Tools for metal forming and blanking

- Plastic molds and extrusion components for abrasion and corrosion resistance, good release, and antibacterial properties

- Hydraulic components – cylinders, pistons, gear pumps

- Valve components – balls, gates, seats, actuators, housings

- Automotive components – crank shafts, cam shafts, gears, bearings, piston rings, tappets, wrist pins, fuel injectors

- Pump components – impellers, diffusers, rotors

- Mechanical seals

| Type of Coating | Diamond Coatings | DLC a(C:H) | DLC aC | DLC taC IFP ® | DLC taC Competitors |

|---|---|---|---|---|---|

| Process | CVD | PACVD | PVD sputter | PVD pulse-arc | PVD light arc |

| Sp3 Fraction | 100 | 40 - 60 | 25 - 40 | 85 - 95 | 70 - 85 |

| Temperature of deposition oC | 850 | 200 | 200 - 400 | < 100 | < 200 |

| Thickness µm | 6-10 | 3 | 1 | 0.05 - 3 | 0.1 - 1 |

| Density g cm-3 | 3.2 - 3.4 | 2.2 - 2.6 | 2.1 - 2.5 | 2.9 - 3 | 3.3 - 3.5 |

| Max temperature resistance (oC) | 600 | 300 | 300 | 500 | < 300 |

| Hardness GPa (Hardness HV 5g) | 40 - 90 | 20 - 40 | 10 - 30 | 85 - 95 | 60 - 85 |

| Adhesion kg mm-2 | Optimal | Good | Good | Optimal | Good |

| Biocompatibility | Optimal | Good | Good | Optimal | Optimal |

| Eletric resistance µficm | 1010 - 1015 | > 1010 | - | 107 - 10 9 | 109 |

DLC resistance to abrasion

DLC TaC’s hardness also makes it durable.

DLC TaC coating protects moving parts from abrasion maintaining smooth movement much longer than uncoated parts. Engines with DLC coated parts create more horsepower reduction of emission, and have longer lifetimes from mechanical parts that rotate, slide, and face other types of wear. For example, DLC is now standard practice on camshafts in all types of Formula 1 racing including cars, motorcycles, and boats.

DLC low coefficient of friction

DLC coatings creater lower coefficients of friction. As friction is the enemy of almost all moving parts, lowering it creates nearly universal improvement, regardless of the industry.

Thus, DLC is found in engines, tools, machining of cast and wrought aluminum, plastic injection molds, pumps, machine parts, bearings, cams, and even razor blades. Reduced friction also reduces the need for lubrication, which improves efficiency within the supply chain from raw material through to the end user.

DLC chemical inertness

DLC coating is an amorphous, stable carbon layer that does not react to acids or alkaline. It is highly resistant against oxidation and corrosion.

The high density and amorphous structure of DLC inhibit corrosive by-products from penetrating into tools. The chemically inert characteristics of diamond-like coatings dramatically reduce possibility of cold welding and material pickup on the surface of the tool